Static Dissipative Film

SDF-2412 Clear Static Dissipative Film

Groundable clear sheet, ideal as a Static Dissipative / ESD / Antistatic retro-fit to static problem surfaces like polycarbonate, acrylic, etc. sheets.

- Antistatic properties

- Electrostatic decay in less than 0.05 second per FederalTest Standard 101C, Method 4046.1. Results in rapid static dissipation without arcing.

- Surface resistivity of 106 - 108 Ω. Provides for ESD control without the need for ionization.

- Permanence in static dissipation performance. Avoids cost of application of temporary topical anti-stats.

- Humidity independent static charge control. Avoids inconvenience of maintaining high levels of humidityand damage caused by such humidity.

- Advanced technology, uniform surface treatment. Avoids charged “hot spots” often found with non-uniformtemporary topical anti-stats.

- Superior optical properties. High clarity polyester film with SDF-2412 surfacing meansoptimum use of available light in glazing applications.

- 90% UV light screen. Reduces UV exposure for light sensitive materials andprocesses.

- High tear and tensile strength polyester film. Adds impact and shatter resistance to glass windows foradded facility security and personnel protection.

- Hard, mar resistant, durable surface. SDF-2412 surface reduces risk of mechanical surface damage.

- Superior chemical resistance. Reduces risk of solvent or chemical surface damage.

- Sheet size: 2.44m x 1.22m x 0.1mm - self-adhesive one side.

It is highly recommended that you use NL-200 interface film for a long bubble free life & ease of removal for as & when needed.

NL-200 Clear Interface Film

Perfect for applying SDF-2412 Static Dissipative film.

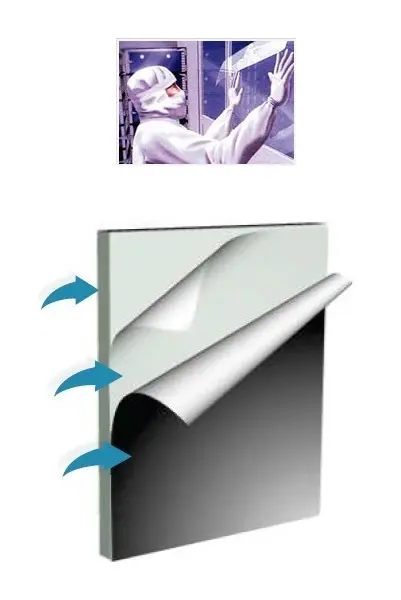

- Top arrow is the substrate, e.g. Polycarbonate, Glass, etc.

- Middle arrow is the NL-200 Interface Film

- Bottom arrow is the Top Film

A thin sacrificial film, optically clear, self-adhesive film, used as an interface that is applied to the surface of polycarbonate, acrylic or most other thermoplastic sheeting or moulding, as well as to glass. It comes off with the top film being replaced, leaving a residue free surface ... ready for the new NL-200 & top film application.

Outgassing is a common problem whan laminating thermoplastic sheets, NL-200 eliminates the issue of outgassing & the subsequent unsightly air & moisture blemishes.

Available by the meter off a 1.525m wide roll.

Please contact the office for more information.