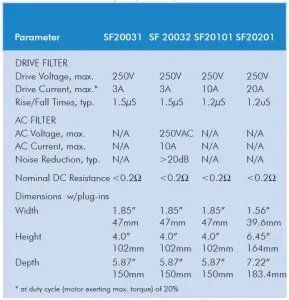

OnFILTER EMI dV/dt Filters for Servo Motors and VFD / VSD

Do you need to improve reliability of your Pulse Width Modulation (PWM) driven motors, comply with IEC60034-17/-25 amd reduce Electro-Magnetic Interfrerence (EMI) and Electrical Overstress (EOS).

Operation of PWM-driven motors, such as servo and Variable Frequency Drives (VFD) / Variable Speed Drives (VSD), causes a number of problems in equipment, including damage to the motor’s bearings from leakage currents from Electrical Discharge Machining (EDM) and to the motor’s insulation. PWM-generated noise also causes errors in operation of electronic equipment. Electronic components processed on PWM-driven tools, such as IC handlers, wire bonders, SMT pick-and-place machines along with many others, can be subjected to EOS, affecting yield and reliability.

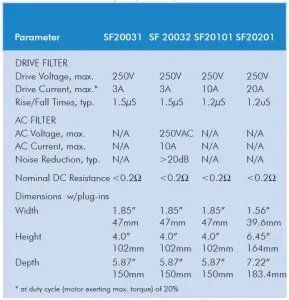

OnFILTER’s SF-series filters substantially reduce high-frequency leakage currents in motors and wiring, assisting in compliance with the requirements of IEC60034-17/-25. They also reduce interfering frequency noise within the tool resulting from operation of PWM-driven motors.

No Mechanical Attachments

The SF series of filters require no mechanical attachments to a motor or shaft. The filters’ small size enables easy installation and unlike the mechanical approach, SF-series filters provide complete EMI reduction, addressing PWM noise problems at its core.

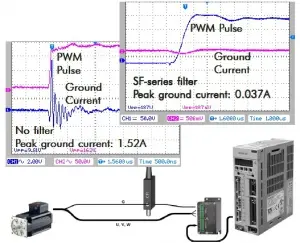

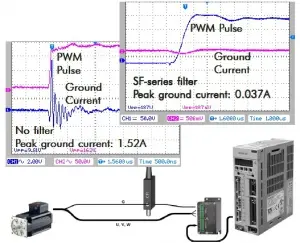

Reduced Ground Noise

SF series filters significantly reduce high-frequency noise on ground, as well as overall EMI in the tool, lowering risk of EOS and reducing errors in automated equipment and testers.

Features

- Reduction of high-frequencycurrents

- Compiance with IEC60034-17/-25

- Prevention of EDM (Electrical Discharge Machining)

- Reduction of overall EMI

- Easy plug-in installation

- No mechanical attachments

- Drive and AC filtering in some models

- Optimized for most PWM motors

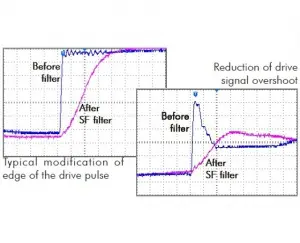

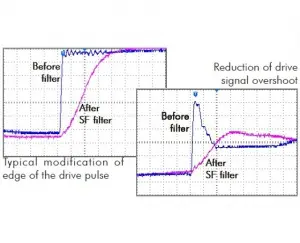

- Effective management of rise and fall times of drive pulses

- Proprietary reduction of ground current